Depending on the type of system being designed and the underlying environment in which it will operate, motor weight can be very important to the overall cost and operating value of the system. Motor weight reduction can be addressed from several directions, including common motor design, efficient component production, and material selection.

To achieve this goal, it is necessary to improve all aspects of electric motor development: from design to efficient production of components using optimized materials, the use of lightweight materials, and novel manufacturing processes.

In general, the efficiency of a motor depends on the type, size, and utilization of the motor, and also on the quality and quantity of materials used. Therefore, from all these aspects, there is a need to develop electric motors using energy and cost-effective components.

A motor is an electromechanical energy conversion device that converts electrical energy into mechanical energy in the form of linear or rotary motion. The working principle of a motor mainly depends on the interaction of magnetic and electric fields.

Many parameters can be used to compare motors: torque, power density, construction, basic operating principle, loss factor, dynamic response, and efficiency, the last being the most important one.

The reasons for low motor efficiency can be mainly attributed to the following factors: improper sizing, electrical inefficiency of the motor used, mechanical inefficiency of the end user (pumps, fans, compressors, etc.), no speed control system, and poor or non-existent maintenance.

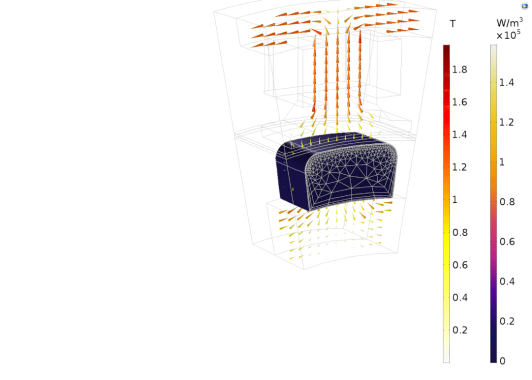

In order to maximize the energy performance of a motor, losses from various energy conversions during the operation of the motor must be minimized. In fact, in an electric motor, energy is transformed from electrical to electromagnetic and then to mechanical.

A motor with increased efficiency differs from a conventional motor because losses are minimized. In fact, in conventional motors, the losses are mainly caused by: Mechanical losses due to frictional and windage losses (bearings, brushes, and ventilation), losses in vacuum iron (proportional to voltage squared), losses due to dispersed energy hysteresis related to flow direction changes, and due to circulation within the core, losses due to eddy currents due to changes in current and flow losses due to the Joule effect (proportional to the square of the current).

1. Proper Design

Designing the most efficient motor is a key aspect of reducing weight, and since most motors are designed for widespread use, the right motor for a specific application is often larger than actually needed.

To overcome this challenge, it is important to look for motor manufacturing companies that are willing to make changes in a semi-custom fashion, from motor windings and magnetics to frame size. To ensure the correct winding is in place, the motor needs to be sized so that the precise torque and speed required by the application can be maintained.

In addition to tuning the windings, manufacturers can also change the magnetic design of the motor based on changes in magnetic permeability. Proper placement of rare-earth magnets between the rotor and stator can help increase the overall torque of the motor.

2. New Manufacturing Process

Manufacturers are able to continually upgrade their equipment to produce motor components with higher tolerances, eliminating thick walls and dense areas that were once used as safety margins against breakage.

As each component is redesigned and manufactured using the latest technology, weight savings can be achieved in several places where magnetic components are included, including insulation and coating, frame, and motor shaft.

3. Material Selection

Material choice has an overall effect on motor operation, efficiency, and weight, which is why so many manufacturers use aluminum frames instead of stainless steel to take the most obvious example.

Manufacturers have continued to experiment with materials with electromagnetic and insulating properties, and manufacturers are using a variety of composite materials as well as lighter metals that offer lightweight alternatives to steel components.

For mounting purposes, a variety of reinforced plastics, polymers, and resins are available, depending on the user’s specific requirements for the final motor. As motor designers continue to experiment and research alternative components, including less dense coatings and resins for sealing purposes, they breathe new life into the production process, which often affects the weight of the motor.

In addition, manufacturers offer frameless motors, which eliminate the impact of the frame on the weight of the motor entirely.

In Conclusion

Technologies that use lightweight materials, new manufacturing processes, and magnetic materials to reduce motor weight and improve motor efficiency.

Electric motors, especially in automotive applications, represent an increasingly future technology. So even though there is still a long way to go, hopefully, this becomes an increasingly consolidated technology where efficiency-enhancing electric motors can address issues related to energy savings.