Ball mill is a mechanical equipment that continues to crush ore or other materials after the crusher to obtain finer particle products required by the process. Its basic principle is to load a certain number of steel balls into its cylinder as grinding media to crush the ore. When the cylinder rotates, the steel balls installed in the cylinder are lifted to a certain height as the cylinder rotates under the action of friction and centrifugal force, and then are thrown down at a certain linear speed. The ore is affected by the falling steel balls. It is crushed by the impact of the ball, as well as the additional crushing and grinding between the steel ball and the steel ball, and between the steel ball and the liner.

With the advent of high-performance neodymium iron boron (NdFeB) permanent magnet materials, permanent magnet motors have achieved a milestone development. NdFeB has a high magnetic energy product, and its residual magnetic induction intensity/coercive force is large. With fewer NdFeB permanent magnets, sufficient motor magnetic energy product can be generated, so the motor volume/size can be greatly reduced. The permanent magnet synchronous motor is suitable for designing with a multi-pole number, which can significantly reduce the height of the stator/rotor core yoke, thereby reducing the amount of iron core and reducing the size of the motor.

New Direct-Start Permanent Magnet Motor (Line-Start PMSM)

In addition to the embedded permanent magnets, the new direct-start permanent magnet motor also has cage-shaped bars with the same structure as the induction motor rotor, which can generate asynchronous torque to accelerate the rotor when powered on. During normal operation, the excitation magnetic field generated by the permanent magnets on the rotor maintains a certain power angle and rotates synchronously with the rotating magnetic field generated by the three-phase winding. When the synchronous speed is stable, the stator magnetic field speed is consistent with the rotor speed, and there is no relative motion, so no induction current is generated. The squirrel cage bars (copper bars) will not work, and the permanent magnets and stator windings will jointly generate driving torque.

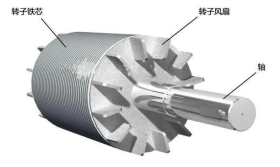

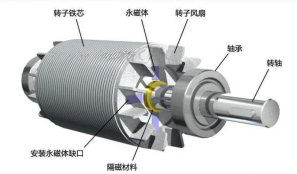

The difference between the asynchronous motor structure rotor: the asynchronous motor is squirrel cage copper excitation, while the LSPM is rotor permanent magnet excitation;

(Structure of copper winding of asynchronous motor rotor)

(Synchronous motor rotor permanent magnet structure)

New Direct-Start Permanent Magnet Motor (Line-Start PMSM)

Low-voltage, medium-speed and direct-start permanent magnet motors (also called “self-starting permanent magnet motors”) have the same advantages as variable-frequency permanent magnet motors:

- The new direct-start series of permanent magnet motors have strong load-bearing capacity, fast dynamic recovery time, and high stable operation performance;

- It has the characteristics of constant speed, high efficiency and power factor, and wide economic operation range;

- Using high-performance NdFeB rare earth permanent magnet materials and low-loss non-oriented electrical steel, the motor is small in size and light in weight;

Compared with variable-frequency permanent magnet motors, it also has the following advantages:

- When a large load is suddenly added or unloaded, there will be no power angle oscillation, no loss of step and inability to operate, and no damage to the motor;

- This product can be started directly at industrial frequency without a frequency converter, can be V/F controlled, and can also be driven by frequency converter speed regulation; (limited to products above 750 rpm) It can realize the use of a frequency converter to drive multiple motors in fan and water pump applications;

- This series of motors can be directly driven by an asynchronous frequency converter without the need to replace a permanent magnet dedicated frequency converter;

The high-voltage, low-speed, direct-drive, three-phase excitation synchronous motor-driven ball mill has the following problems:

Low efficiency: The existing three-phase excitation synchronous motor drive mode has high energy consumption and low efficiency. The motor needs to be equipped with a special external excitation system to provide the rotor with excitation current to generate an excitation magnetic field, which interacts with the stator rotating magnetic field, so that the rotor generates torque and realizes the rotation of the motor. Therefore, additional excitation energy is consumed, resulting in low motor efficiency.

Low reliability: The three-phase excitation synchronous motor has a complex excitation system (excitation winding, slip ring, excitation power supply system, etc.), which is relatively larger in size and weight, complex in structure, strict in production process, low in system reliability, and large in maintenance workload. In addition, the magnetic field strength of the three-phase excitation synchronous motor needs to be precisely controlled by the control system, so the control system has high requirements.

High maintenance: Three-phase excitation synchronous motors have a complex excitation system. Excitation windings and slip rings need to be maintained every few years, and the maintenance cost is relatively high;

Troublesome loading and unloading: During the disassembly and assembly of medium and large power three-phase excitation synchronous motors, the stator, rotor and supporting components need to be disassembled and assembled, which requires high precision and is time-consuming and labor-intensive.

The high-voltage direct-drive new direct-operation permanent magnet motor has the same voltage and rated speed as the three-phase high-voltage excitation synchronous motor, and the starting system has all the functions of variable frequency starting, industrial frequency operation and one-to-many. First, the ball mill at the rear end is driven to start slowly at a low speed through the starting cabinet. When the rated speed is reached, the permanent magnet direct-drive motor is switched to industrial frequency operation through the conversion system. After normal operation, it is the same as the original three-phase high-voltage excitation synchronous motor, without any adjustment. The motor saves efficiency according to the change of material load;

Therefore, in the actual normal operation process, there is no loss of high-voltage frequency conversion and transformer (accounting for more than 4.5% of the system energy saving), the whole system has higher power saving efficiency, and the starting cabinet can achieve the effect of starting multiple three-phase synchronous high-voltage excitation motors with one cabinet, realizing one-to-many comprehensive control, and multiple motors can share a set of starting switching system, which can effectively reduce costs.