01 What is an electric roller?

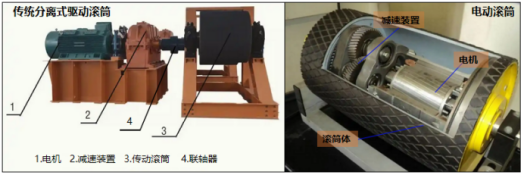

The electric roller integrates the motor and the reduction device into the roller. It does not require a traditional coupling. The motor in the roller directly drives the roller to rotate. Its structure is roughly composed of a motor, a reduction device, a roller body, and a sealing device. Compared with the traditional separate drive roller, the coupling is reduced. The permanent magnet electric roller does not even require a reduction device to achieve a stepless speed regulation function within a wide range.

Comparison chart of traditional separate drive roller and electric roller

Motor: The motor is the power source of the electric roller. Different application scenarios have slightly different motor selections to meet diverse work needs. Common motor types include asynchronous motors and permanent magnet synchronous motors. Asynchronous motors are widely used in electric rollers due to their simple structure, low cost, and reliable operation. Permanent magnet synchronous motors are increasingly recognized by users due to their small size (no reduction device required), low energy consumption, and high torque.

Reduction device: In order to achieve the required operating speed in the production process, it is usually necessary to install a reduction device behind the motor to achieve precise control and increase torque to meet the actual conveying requirements in work. The reduction device usually adopts gear reduction or worm gear reduction. Gear reduction has the characteristics of high transmission efficiency, high precision, and long life; worm gear reduction has a large transmission ratio and good self-locking performance, which is suitable for some occasions that require large torque and have requirements for installation space.

Drum body: This is the main part of the electric drum. The drum body is directly installed under the conveyor belt for material transportation. The materials used for the drum body vary greatly according to the application scenario. It is usually made of high-quality steel with sufficient strength and wear resistance to ensure that it will not deform or wear too quickly during long-term use.

Sealing device: In order to prevent dust, moisture and other impurities from entering the electric drum, the electric drum also needs to have a good seal. And while sealing, it is necessary to ensure the heat dissipation inside the electric drum.

02 Types of electric rollers

There are many types of electric rollers, and the energy-saving effects of different types of electric rollers are also quite different. At present, the main classification of electric rollers is divided according to the type of motor, which is divided into three categories: asynchronous electric rollers, permanent magnet synchronous electric rollers, and brushless DC electric rollers.

Permanent magnet synchronous electric roller: A permanent magnet synchronous motor is placed in the drum body, and a wide range of speed regulation does not require a reduction device. It is suitable for medium and large power applications, such as coal mines, steel, non-ferrous metals and other industries. At present, my country’s permanent magnet synchronous electric roller has exceeded 1000kW. Compared with the traditional separate drive device, the permanent magnet synchronous electric roller reduces the coupling and reduction device, and the permanent magnet motor has a higher transmission efficiency than the asynchronous motor, and the energy-saving effect is the best.

Brushless DC electric roller: A DC brushless motor + reduction device is placed in the drum body, which is suitable for low-power applications, such as food, medicine, packaging and other industries, and the power range is usually from a few hundred watts to a few kilowatts. Brushless DC electric rollers can achieve modular operation, and can match the number of electric rollers according to the transportation load to achieve precise control and modular operation. Brushless DC electric rollers have low power and account for a small proportion of the total energy consumption of enterprises, so people do not feel their energy-saving effect deeply.

Asynchronous electric rollers: Asynchronous motors + reduction devices are placed in the drum body, which are suitable for small and medium-sized power applications, such as logistics, building materials, port transportation, grain transportation, and high-energy-consuming manufacturing industries such as papermaking. The power range is usually from a few kilowatts to hundreds of kilowatts. Compared with traditional separate drive devices, asynchronous electric rollers mainly reduce couplings, and the energy-saving effect is slightly lower than the previous two types of electric rollers.

03 How to achieve energy conservation and emission reduction with electric rollers

Electric rollers have many advantages, such as high transmission efficiency, small size, low noise, intelligent operation, and convenient maintenance, which significantly improve the energy-saving effect of enterprises:

High transmission efficiency and significant energy-saving effect: Electric rollers reduce couplings and have higher transmission efficiency; some permanent magnet electric rollers do not even require reduction devices, and their transmission efficiency is more significantly improved than that of traditional separate drive rollers, which makes a huge contribution to the energy conservation and emission reduction of enterprises.

Small size, light weight, space saving, and material saving: Traditional separate drive rollers, whose motors and reduction devices are installed on the side of the rollers, require larger placement space, while the motors and reduction devices of electric rollers are placed inside the rollers, which are smaller in size, use fewer materials and parts, and are lighter in weight. During the installation and operation of the equipment, it is more convenient and energy-saving.

Lower noise, reducing the energy and material costs of noise reduction treatment for enterprises: The motors and reduction devices of electric rollers are inside the rollers, which effectively reduce the noise in the working environment and reduce the energy and material consumption caused by the need to deal with noise pollution in some enterprises.

Intelligent and modular operation is more energy-saving: Traditional separate drive rollers often consume a lot of electricity in idling or unnecessary operation because they cannot accurately control power output; electric rollers can be intelligent and modular, and can adjust the operating parameters of the motor in real time according to workload and operating conditions, achieve precise speed control and torque output, further optimize energy utilization, and significantly improve energy conservation and emission reduction for enterprises.

Easy maintenance, saving manpower and energy consumption: Traditional separate drive rollers have couplings and reduction devices, so they need to consume a lot of oil for lubrication during daily maintenance work, and also require frequent maintenance by staff.

The electric roller eliminates the need for oil change and maintenance of couplings and reducers, making daily maintenance more convenient and efficient, saving labor costs, material costs and energy consumption for enterprises.

Conclusion

Compared with traditional separate drive rollers, the energy-saving effect of electric rollers is significantly improved. According to data from the China Heavy Machinery Industry Association, the annual output value of my country’s belt conveyor equipment industry exceeds 12 billion yuan, and the annual demand for drive devices for conveying equipment exceeds one million kilowatts. The large-scale application of electric rollers will significantly improve the energy saving of the entire belt conveyor equipment industry.