Abstract: Analyze the problems existing in the original cooling tower fan drive structure, introduce the advantages of the permanent magnet direct drive motor, and analyze its selection and control. The cooling tower fan drive system is transformed into a permanent magnet motor direct drive system, which solves the problem of equipment problems such as oil leakage and large vibrations, maintenance has been reduced, equipment operation efficiency has been improved, and the power saving effect is obvious. A single unit can save about 98,000 kWh of electricity per year, and the use effect is good.

The waste heat power generation circulating water cooling system uses two 75 kW cooling tower fans for circulating water cooling. The cooling fan transmission part adopts the traditional equipment drive structure of motor + transmission shaft + reducer. The motor and reducer input shaft are connected to a steel transmission shaft.

1. Problems with traditional drive structures

(1) The reducer of the cooling fan is installed inside the cooling tower. The transmission shaft is 4 m long. Due to the very humid environment, the transmission shaft is severely corroded. The transmission shaft loses its dynamic balance due to the uneven shedding of the rust layer, causing serious vibration of the equipment and the transmission shaft. Regular rust removal and dynamic balancing are required, which is expensive.

(2) As the running time of the cooling fan reducer increases, the input shaft oil seal wears seriously, causing oil leakage, requiring regular oil replenishment, and polluting the environment.

(3) The reducer has a compact structure, generates a lot of heat, and has weak heat dissipation capabilities, resulting in the high temperature of the reducer, the short lifespan of oil seals and lubricants, and the need for frequent maintenance.

2. Permanent magnet direct drive structure and advantages

The permanent magnet direct drive motor adopts variable frequency vector control technology, low speed and high torque direct drive technology, and intelligent control technology. It has a simplified structure and has the characteristics of high efficiency and low consumption, low speed and high torque, high reliability and maintenance-free, high stiffness and fast response, and no need for lubrication. The low speed, smooth operation, and small vibration greatly reduce the workload of daily maintenance and repair, saving manpower and material costs. Suitable for use in cooling fan scenarios.

Main advantages:

(1) The permanent magnet direct drive motor directly drives the load, eliminating the need for a reducer. It has a simple and reliable structure and is basically maintenance-free.

(2) The reducer and transmission shaft are removed, and the system transmission efficiency is 0.93. When operating below the rated frequency, it has constant torque characteristics, which meet the heavy-load startup requirements of the equipment and make the equipment operation more energy-saving.

(3) The equipment occupies a small space and does not consume lubricating oil and reducer spare parts.

(4) Frequency converter control can achieve a soft start, reducing the impact on load equipment and extending its service life.

(5) Under low load conditions, the operating frequency can be appropriately reduced to achieve better energy-saving effects.

3. Selection of permanent magnet direct drive motor

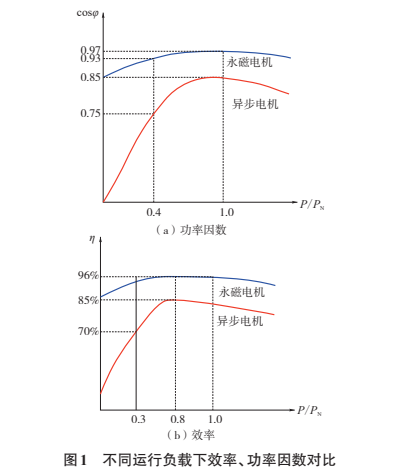

3.1 Load operation power factor and efficiency comparison

Before the transformation, the power of the cooling tower fan was 75 kW, the rated current was 160 A, the maximum operating current was about 76 A, and the load rate was about 56%. The comparison of the efficiency and power factor of asynchronous motors and permanent magnet motors under different operating loads is shown in Figure 1.

The permanent magnet direct drive motor has the same impeller speed as the cooling tower fan, n0=n=155 r/min (n is the fan speed), the required shaft power P=1.732UIcosφη1η2η3=1.732×0.38×76×0.855×0.86× 0.95×0.96≈33.5 (kW), the required torque T=9 550P/n0=9 550×33.5÷155= 2 064 (N·m).

The actual model after modification is shown in Figure 2.

3.2 Disadvantages of permanent magnet motors

Permanent magnet synchronous motors generally choose rare earth permanent magnet materials (neodymium iron boron) as permanent magnets. Currently, rare earth materials are relatively expensive and the initial investment cost is high. When the temperature of a rare earth permanent magnet synchronous motor is too high, it may undergo irreversible demagnetization under the action of the armature reaction caused by the impact current, or during severe mechanical vibration, causing the motor performance to degrade or even become unusable. Therefore, in the use environment, attention should be paid to the formulation of motor cooling plans and measures to prevent vibration.

4. Effect analysis after transformation

After the cooling tower fan motor adopts two 55 kW permanent magnet direct drive motors, under the same operating conditions, the current per hour of a single permanent magnet motor decreases by about 35 A in autumn and winter on average, and the measured voltage during operation is about 340 V. Take U= 340 V, cosφ=0.97, η=0.95, then the power is P=1.732UIcosφη=1.732×0.34×35×0.97×0.95=18.9 (kW), and it is expected to save 18.9 kWh per hour. The average hourly current decrease is about 28 A in spring and summer, and the actual measured voltage during operation is about 370 V. Taking U=370 V, cosφ=0.97, η=0.95, the power is: P=1.732UIcosφη=1.732×0.37×28×0.97× 0.95=16.5 (kW), it is expected to save 16.5 kWh per hour. According to the comparison of the energy meter measurement data before and after the transformation, a single motor can save 17 kWh per hour in autumn and winter, and a single motor can save 15 kWh per hour in spring and summer. Calculated based on an annual operation rate of 70%, a single motor can save 17 kWh per hour in autumn and winter. Electricity saving is about 98,000 kWh.

5. Conclusion

After the cooling tower fan drive system was transformed into a permanent magnet motor direct drive system, the problems of oil leakage and large vibration of the equipment were solved, the operating efficiency of the equipment was improved, and the power saving effect was obvious, saving about 15~17 kWh per hour, and the power saving rate 40%, while reducing maintenance, improving system operation rate and extending equipment service life.