As an important component of the motor, the winding is an important part that converts electrical energy into mechanical energy when the motor is in use. Although it is protected by the casing in the center of the motor, the winding will also fail, mainly due to excessive motor current, excessive power supply voltage fluctuations, single-phase operation, mechanical bruises, etc., resulting in insulation damage, short-circuit faults in the motor windings, which will affect the normal operation of the motor, and it is a fault that is more harmful to rotating equipment.

Motor winding faults can be divided into: winding turn-to-turn short circuits, winding short circuits, winding pole short circuits, winding phase short circuits, etc.

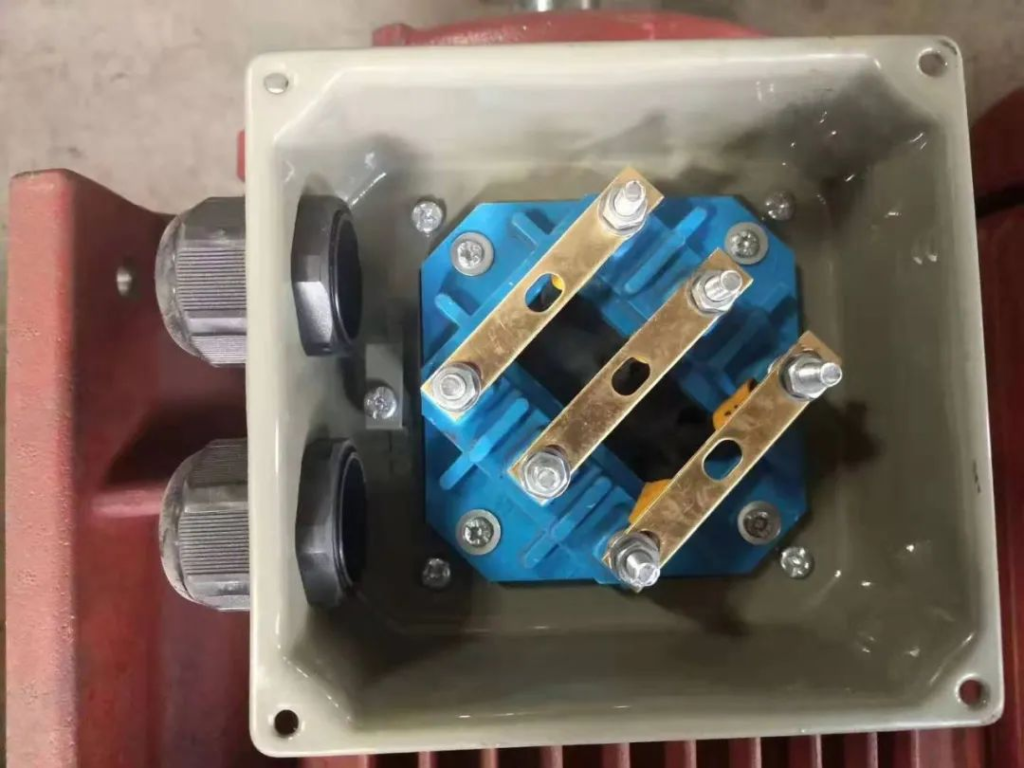

The picture above: If the cause of the motor with winding short circuit and burnt is unknown, improper handling will often result in half the effort, which will reduce the service life of the motor, increase the maintenance cost, and even cause the winding to burn out. Therefore, quickly judging the cause of the winding short circuit fault and taking appropriate measures to solve it is the guarantee for the continuous and safe operation of the equipment. Today, I will take stock of the causes and repair methods of motor winding short circuit faults.

1. Fault phenomenon

The uneven distribution of the magnetic field of ions and the unbalanced three-phase current make the motor vibrate and noise aggravate when it is running. In severe cases, the motor cannot start, and a large short-circuit current is generated in the short-circuited coil, causing the coil to heat up rapidly and burn out.

2. The cause is that the motor is overloaded for a long time, which causes the insulation to age and lose its insulation effect; the insulation is damaged when the wire is embedded; the insulation resistance of the winding is damp and the insulation resistance decreases, resulting in insulation breakdown; the end and interlayer insulation materials are not properly matted or damaged when they are shaped; The insulation of the connecting wire is damaged; the insulation is broken down by overvoltage or lightning strike; the rotor and the end of the stator winding rub against each other to cause insulation damage; metal foreign objects fall into the interior of the motor and there is too much oil.

3. Inspection method

(1) External observation method. Observe whether the junction box and the end of the winding are burnt. After the winding is overheated, it will leave dark brown and smell bad.

2) Temperature detection method. Run without load for 20 minutes (stop immediately if the abnormality is found), and use the back of your hand to feel whether the temperature of each part of the winding exceeds the normal temperature.

(3) Electricity test method. Use an ammeter to measure, if the current of a certain phase is too large, it means that there is a short circuit in this phase.

(4) Bridge inspection. Measure the DC resistance of each winding, generally, the difference should not exceed 5%, if it exceeds, the phase with the smaller resistance has a short circuit fault.

(5) Short-circuit detector method. If there is a short circuit in the winding under test, the steel sheet will vibrate.

(6) Multimeter or megger method. Measure the insulation resistance between any two-phase windings. If the reading is extremely small or zero, it means that there is a short circuit between the two-phase windings.

(7) Voltage drop method. After the three windings are connected in series, the low-voltage safe alternating current is connected, and it is measured that the group with a small reading has a short-circuit fault.

(8) Current method. When the motor is running without load, first measure the three-phase current, and then measure and compare the two phases. If it does not change with the power supply, there is a short circuit in the one-phase winding with the larger current.

4. Short circuit treatment method

(1) The short-circuit point is at the end. Insulation materials can be used to separate the short-circuit point, and the insulated wire can also be re-wrapped, and then painted and re-dried.

(2) Short circuit in the wire slot. After softening it, find out the short-circuit point and repair it, put it back into the trunking, and then paint and dry it.

(3) For each phase winding with short-circuit turns less than 1/12, cut off all the short-circuit lines when the number of turns is connected in series, and connect the conductive parts to form a closed loop for emergency use.

(4) When the number of turns at the short-circuit point of the winding exceeds 1/12, it must be completely removed and rewound.