1. The characteristics of variable frequency motor

1.1 Electromagnetic design

For ordinary asynchronous motors, the main performance parameters considered in the design of variable frequency motors are overload capacity, starting performance, efficiency, and power factor. As for the frequency conversion motor, since the critical slip is inversely proportional to the power frequency, it can be started directly when the critical slip is close to 1.

Therefore, the overload capacity and starting performance no longer need to be considered too much, and the key problem to be solved is how to improve the motor’s adaptability to non-sine wave power. First, reduce the stator and rotor resistance as much as possible.

Reducing the stator resistance can reduce the fundamental copper loss to compensate for the increase in copper loss caused by high-order harmonics. Secondly, in order to suppress the higher harmonics in the current, it is necessary to increase the inductance of the motor appropriately. However, the leakage reactance of the rotor slot is large, the skin effect is also large, and the copper loss of high-order harmonics also increases.

Therefore, the size of the motor leakage reactance should take into account the rationality of impedance matching in the entire speed range. In addition, the main magnetic circuit of the variable frequency motor is generally designed to be in an unsaturated state. One is to consider that high-order harmonics will deepen the saturation of the magnetic circuit, and the other is to consider that at low frequencies, the output voltage of the inverter should be appropriately increased in order to increase the output torque.

1.2 Structural Design

When designing the structure, the influence of non-sinusoidal power characteristics on the insulation structure, vibration, and noise cooling methods of the variable frequency motor is mainly considered. First of all, in terms of insulation level, it is generally F level or higher, and the ground insulation and turn insulation intensity are strengthened, especially the ability of insulation to withstand impact voltage should be considered. For the vibration and noise problems of the motor, it is necessary to fully consider the rigidity of the motor components and the whole, and try to increase its natural frequency to avoid resonance with each force wave.

Generally, forced ventilation is used for cooling, that is, the cooling fan of the main motor is driven by an independent motor. Bearing insulation measures should be used for motors with a capacity of more than 160KW, mainly because it is easy to generate magnetic circuit asymmetry and shaft current. When the currents generated by other high-frequency components work together, the shaft current will increase greatly, resulting in bearing damage, so insulation measures are generally taken.

In addition, for constant power variable frequency motors, when the speed exceeds 3000/min, special grease with high-temperature resistance should be used to compensate for the temperature rise of the bearing.

2 Diagnosis of common faults of variable frequency motors

2.1 Turn-to-turn short circuit, partial discharge

Turn-to-turn short circuits and partial discharges are relatively common forms of insulation faults in variable-frequency motors. Among them, a turn-to-turn short circuit generally manifests as a large area of damage to one of the coils in the motor, and partial discharge is concentrated in the appearance of the motor coil. But the insulation resistance has been shown to be zero. At this time, the damage to the motor insulation system is not only caused by a single factor but also caused by partial discharge, local medium heating, and other factors.

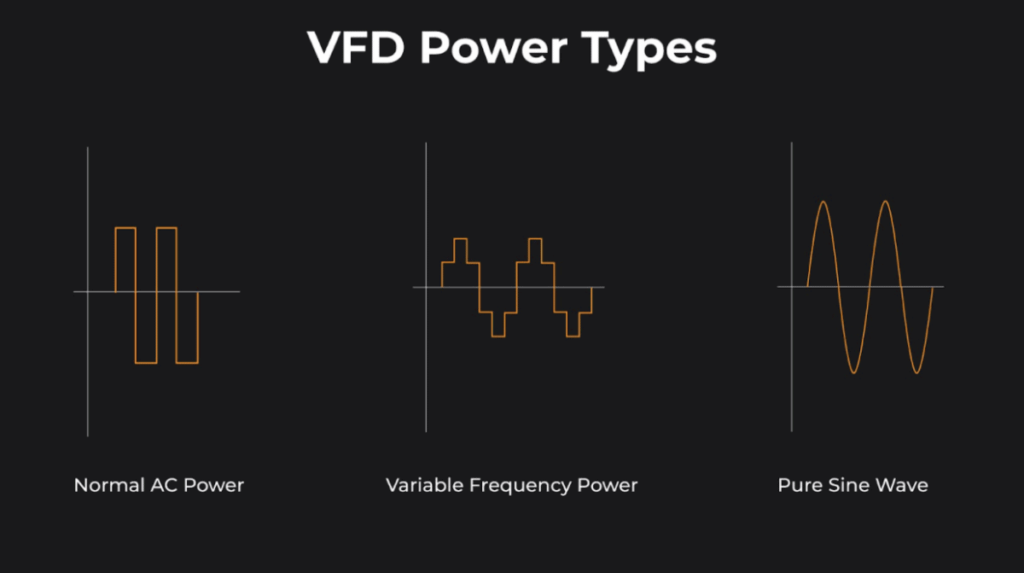

Partial discharge: At present, in the operation process of small and medium-capacity inverters, the pulse width modulation technology of IGBT power devices is generally used. The PWM speed control device composed of these components can provide towering peaks, and the peaks have steep front characteristics. At the same time, its modulation frequency is higher, so the harm to the insulation is more serious.

Local medium heating: If the electric field strength E in the motor has obviously exceeded the insulation critical value, the loss of the medium will become more and more serious. Especially in the situation of increasing frequency, the partial discharge will also increase, thereby generating heat, which will inevitably bring about more serious problems such as leakage current. Over time, not only will the loss per unit volume increase, but also the temperature rise of the motor will continue to rise, which will virtually lead to faster and faster insulation aging.

Cyclic alternating stress: Through the power supply mode of PWM variable frequency power supply, when the variable frequency motor is put into formal use, it can directly brake through various methods provided by the frequency converter. Under the influence of cyclic variable stress, the insulation aging speed of the motor will be faster and faster. Since the electrical and mechanical integrity was not comprehensively considered in the early design process, the aging process of the motor will continue to increase.

2.2 Bearing damage, excessive vibration

Combined with the effect of the PWM inverter drive system when it is put into formal operation, the bearing damage problem of the entire frequency conversion motor will become more and more serious, and even problems such as bearing damage and excessive vibration often occur. After a 690kW variable frequency motor in a high-speed wire factory was put into use, problems such as serious vibrations began to appear in just 3 months. When performing fault diagnosis and maintenance for this problem, the motor was disassembled offline, and it was found that there were many burning spots on the surface of the bearing, and these burning spots were also relatively obvious. The reason was that the bearing of the motor was seriously damaged due to the influence of the shaft current.

2.3 Current oscillation

When analyzing with examples, there is a 250kW/400V/430A variable frequency motor system in a cold rolling plant, and the problem of burning components has occurred continuously when it is running. When carrying out maintenance and treatment for the frequency converter, the V/F control no-load test operation was carried out on the motor in advance.

According to the test results, it was found that the motor current was abnormal in the range of 7 to 30 Hz, and more importantly, the amplitude of the three-phase current has obvious oscillation, and the highest oscillation current amplitude can reach 700A. After the fault problem occurred, relevant maintenance personnel immediately carried out tests on the existing motors and frequency converters of the same type. According to the test results, it was found that the motors and frequency converters within the same frequency range were unstable. Near the power frequency, the state of the motor is relatively stable, but if it is at a frequency of 40Hz, especially in the range of 20 to 30Hz, the current of the motor will oscillate at a period of about 10 to 20Hz. If the peak value at this time is too high, the motor and the entire operation of the system will be seriously affected.

To analyze this situation, for asynchronous motors, if the slip rate is zero, there will be unstable factors in the positive and negative changes of the transient torque. More importantly, the torque ripple driven by the inverter, the transient change of V/F will cause a more obvious torque ripple, which may evolve into vibration, or even continue to vibrate. In this situation, there is a certain correlation between the torque ripple and harmonic current and other factors.

If the variable frequency motor is running, its running state is unstable, and it must not be simply considered that the motor or the frequency converter is faulty, but it is necessary to comprehensively analyze the parameters of the motor and the frequency converter, so as to make a reasonable judgment on the fault.

3. Maintenance measures for frequency conversion motor failure

Frequency conversion motors are more and more widely used. For the maintenance of frequency conversion motors, it is necessary to take effective measures according to the characteristics of frequency conversion motors to ensure the normal operation of frequency conversion motors.

3.1 Requirements for maintenance of variable frequency speed regulating motor

Frequency conversion speed regulation motors generally choose 4-stage motors, the base frequency operating point is designed at 50Hz, the motor operates with constant torque within the frequency range of 0-50Hz (speed 0-1480r/min), and the frequency is 50-100Hz (speed 1480-2800r/min) The motor operates at constant power within the range of min), and the entire speed regulation range is (0-2800r/min), which basically meets the requirements of general driving equipment. Its working characteristics are the same as those of DC speed regulation motors, and the speed regulation is smooth and stable.

If you want to increase the output torque within the range of constant torque speed regulation, you can also choose a 6-level or 8-level motor, but the volume of the motor is relatively larger. Since the electromagnetic design of the variable frequency speed regulating motor uses flexible CAD design software, the fundamental frequency design point of the motor can be adjusted at any time, and we can accurately simulate the working characteristics of the motor at each fundamental frequency point on the computer.

The constant torque speed regulation range of the motor has been expanded. According to the actual working conditions of the motor, we can increase the power of the motor within the same frame size, or use the same frequency converter to increase the power of the motor. The output torque is raised higher to meet the design and manufacture of the motor in the best state under various working conditions.

The variable frequency speed regulating motor can be equipped with an additional speed encoder, which can realize the advantages of high precision speed, position control, and fast dynamic characteristic response. It can also be equipped with a special DC (or AC) brake for the motor to achieve fast, effective, safe, and reliable braking performance of the motor.

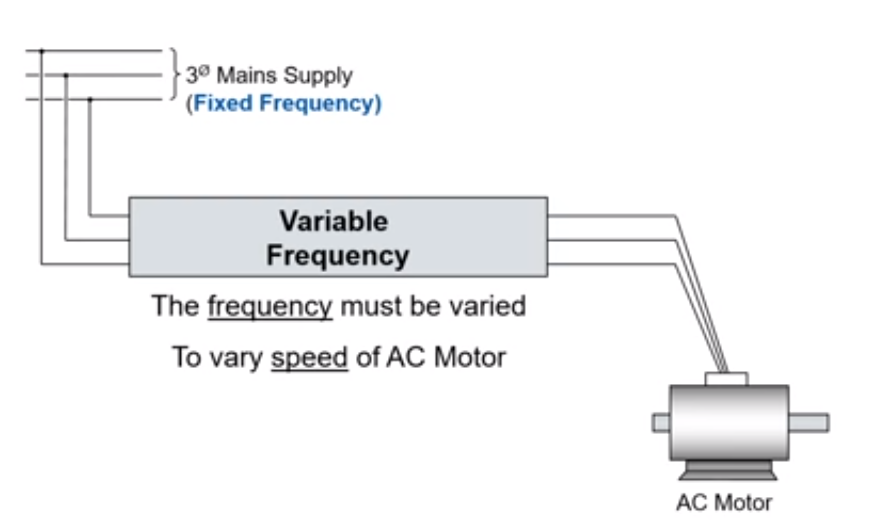

Due to the adjustable base frequency design of the variable frequency speed regulating motor, we can also manufacture various high-speed motors that maintain the characteristics of constant torque during high-speed operation, replacing the original intermediate frequency motors to a certain extent, and the price is low. The variable frequency speed regulating motor is a three-phase AC synchronous or asynchronous motor. According to the output power of the inverter, there are three-phase 380V or three-phase 220V, so the motor power supply also has three-phase 380V or three-phase 220V.

Generally, the inverter below 4KW only has three phases 220V, since the variable frequency motor is divided into different constant power speed regulation areas and constant torque speed regulation regions by the base frequency point (or inflection point) of the motor, the settings of the frequency converter base frequency point and the frequency conversion motor base frequency point are both very important.

3.2 Improve insulation performance

The rational use of corona-resistant enameled wire is conducive to appropriately increasing the screen paint film layer. Through the application of quantum chemistry technology, the chemical materials used for shielding can directly participate in the polycondensation reaction of paint-based polymers as the main material of the paint film, ensuring the high-frequency impulse withstand voltage can be dispersed and dissolved in time to improve the overall corona resistance of the paint film. The slot insulation material is currently made of several different mixtures such as NHN and F-grade DMD. This type of material has strong organic characteristics, so it does not have corona resistance. Based on this, a new type of slot insulation containing mica is selected to be used, and the addition of mica is beneficial to improve the corona resistance.

In terms of phase-to-phase insulation, the product type with polyester fleece on the surface should be selected. Compared with other materials, this type of product has obvious advantages in absorbing resin, which is conducive to forming an effective bond with the wire.

The impregnation process has always been one of the most important processes in the maintenance of variable frequency motors. The most important point is to avoid resin outflow. Usually choose to use VPI for treatment, or after VPI treatment, the impregnation process can be added appropriately, which is conducive to eliminating the air bubbles in time, continuously filling the air gap in the winding, and can also improve the electrical and mechanical strength of the winding to ensure Its own heat resistance and stain resistance are strengthened. If conditions permit, it can be treated by ultraviolet heating and the current drying method, which can achieve good results.

In addition, it should be noted that during the entire maintenance process of the variable frequency motor, avoid short circuits and other problems, ensure that the assembly of various components such as motor bearings can meet the basic accuracy requirements, and try to avoid serious local heating caused by eddy current loss and other problems, otherwise, it will inevitably affect the insulation performance of the motor.

3.3 Eliminate the influence of shaft current

In order to ensure that the shaft current can be reduced to a harmless level, it is usually necessary to ensure that the shaft current is controlled below 0.4A/mm2 or 0.35mV. Based on this, targeted countermeasures should be taken in combination with the specific use environment and type characteristics of the motor to eliminate the adverse effects of the shaft current.

Suppression of power supply harmonics: In order to eliminate the influence of shaft current, through the reasonable application of the inverter power supply speed control system, you can directly add filters to it, or use the matching frequency conversion speed control device, which is conducive to reducing harmonics. At the same time, it can also reduce the adverse effects of shaft current and vibration.

Bearing insulation measures: Taking targeted insulation measures for bearings can also eliminate the adverse effects of shaft current in time. At present, the common method is to ground the bearing on the load side of the motor and insulate the bearing on the non-load side. When using the rolling bearing structure, you can choose to use the insulating bearing as the main bearing form, or on the surface of the inner ring and outer ring of the bearing. Use the ion spraying method to evenly spray the insulating layer of 50 to 100mm. In addition, according to the actual situation, a sleeve can be directly added to the bearing chamber of the end cover, and an insulating layer is added between the sleeve and the end cover to fasten the inner and outer cover bearings. When using the sliding bearing structure, you can directly add epoxy glass cloth pads to the position of the fixed bearing, or add insulating pipe joints at the position of the oil inlet and outlet pipelines. Using these methods can effectively eliminate the adverse effects of the shaft current.

When eliminating the shaft current, in addition to the above methods, you can also choose to use the monitoring line to strengthen the insulation performance and improve the motor operating environment and other strategies. All in all, no matter which method you choose to use, you must start from multiple angles according to the characteristics and requirements of the actual situation in order to achieve good results.

3.4 Eliminate the influence of shaft current

In order to ensure that the shaft current can be reduced to a harmless level, it is usually necessary to ensure that the shaft current is controlled below 0.4A/mm2 or 0.35mV. Based on this, targeted countermeasures should be taken in combination with the specific use environment and type characteristics of the motor to eliminate the adverse effects of the shaft current.

Suppression of power supply harmonics: In order to eliminate the influence of shaft current, through the reasonable application of the inverter power supply speed control system, you can directly add filters to it, or use the matching frequency conversion speed control device, which is conducive to reducing harmonics. At the same time, it can also reduce the adverse effects of shaft current and vibration.

Bearing insulation measures: Taking targeted insulation measures for bearings can also eliminate the adverse effects of shaft current in time. At present, the common method is to ground the bearing on the load side of the motor and insulate the bearing on the non-load side. When using the rolling bearing structure, you can choose to use the insulating bearing as the main bearing form, or on the surface of the inner ring and outer ring of the bearing. Use the ion spraying method to evenly spray the insulating layer of 50 to 100mm. In addition, according to the actual situation, a sleeve can be directly added to the bearing chamber of the end cover, and an insulating layer is added between the sleeve and the end cover to fasten the inner and outer cover bearings. When using the sliding bearing structure, you can directly add epoxy glass cloth pads to the position of the fixed bearing, or add insulating pipe joints at the position of the oil inlet and outlet pipelines. Using these methods can effectively eliminate the adverse effects of the shaft current.

When eliminating the shaft current, in addition to the above methods, you can also choose to use the monitoring line to strengthen the insulation performance and improve the motor operating environment and other strategies. All in all, no matter which method you choose to use, you must start from multiple angles according to the characteristics and requirements of the actual situation in order to achieve good results.

3.5 Improve the current oscillation problem

After long-term experiments, summarization, and analysis, in order to ensure the effective treatment of the current oscillation problem and improve the unstable current situation, it can be realized by continuously increasing the motor inertia or loading, or by appropriately increasing the voltage type inverter DC side capacitance, which is conducive to reducing the impact of voltage fluctuations.

Combined with the operating status of the PWM-controlled inverter, using fast switching elements or directly reducing the modulation frequency of the PWM is beneficial to avoid fluctuations in the output voltage due to the influence of the dead zone. In order to improve the problem of current oscillation, it is also possible to use a motor with a high slip rate and use methods such as current feedback to ensure that the vector control of the circuit can be fed back in time, so as to ensure the improvement of the operating stability of the variable frequency motor.