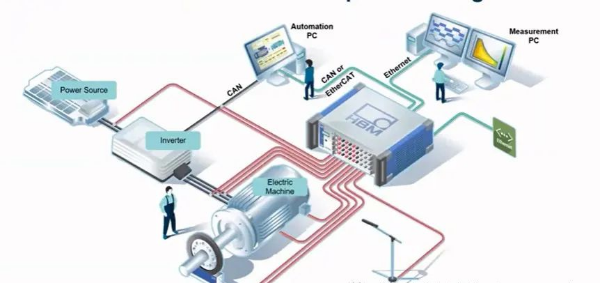

An electric motor test stand or test bench is a test stand for reproducible testing of electric motors. In addition to the mechanical design, an electric motor test stand also includes accompanying measurement devices, sensors and application software.

For example, bus systems are used to control and monitor the test objects. There are different types of test stands, such as developmental test stands, endurance test stands, end-of-line test stands and hardware-in-the-loop test stands.

Electric machines are usually tested to determine characteristic curve points or entire characteristic curves. Other tests are performed to characterize the electromagnetic behavior of the test object: for example, generative measurements, cogging torque measurements, discharge measurements.

1. Operational modes

1.1 Classic testing

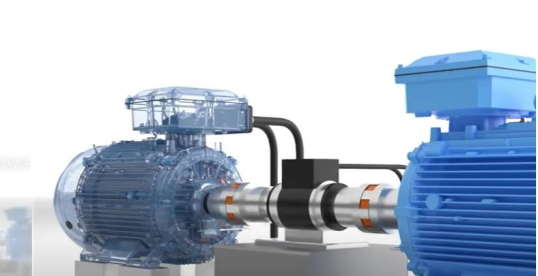

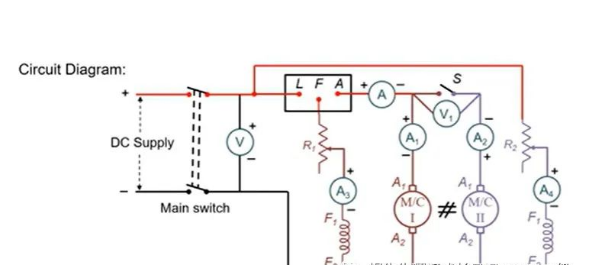

A typical test setup consists of a load machine, clutch and torque transducer. An external load is used to apply the strain, i.e. the load, to the motor. Using this method, simple characteristics can be obtained directly and mechanically and derived variables calculated. From the input current and input voltage, the absorbed power is known. Similarly, from the speed and torque output values, the mechanical power output and thus the efficiency of the motor can be determined.

Advantages

– It is possible to test different types of motors

– It is not necessary to change the test algorithm

– After adapting, further tests are easy to implement

Disadvantages

– Mechanical modification is required every time a motor or shaft is changed

– Systematic errors in the test sequence may occur if the test is incorrectly parameterized

– It takes a time-consuming process to adapt the test object to the test bench before the test can be carried out.

1.2 Parameter identification method

Using the test object’s own inertia to dynamically run through the characteristic curve: This method tests the motor without mechanical coupling and does not measure torque and speed. The test is performed using terminal voltage and current values. Parameters are determined using mathematical models.

Advantages

– Simple design

– Fast

– No need to adjust for different motor types

– Only current and voltage are measured

– No mechanical quantities are measured

Disadvantages

– Model needs to be adjusted for different motors

2. Other tests

2.1 Noise analysis

Noise analysis is performed by means of a suitable excitation function. The test function should be chosen so that all noise-generating forces can be analyzed by means of the respective sensors. The most common noise sources are: rolling bearings, commutators and electric forces.

2.2 Regenerative testing

A motor energized and driven from the outside induces a voltage that can be measured on the motor’s connection lines. The induced voltage is proportional to the speed and excitation.

The course of the induced voltage gives characteristic information about the windings and the excitation of the circle. The measurement of the induced voltage allows a simple diagnosis of the electromagnetic properties of the motor. Regularities are derived from a moving conductor loop in a constant magnetic field.

2.3 Measuring cogging torque

In a rotating electrical machine, the number of poles in the rotor multiplied by the number of strands in the stator equals the number of preferred stable positions in which the rotor can move. The magnitude of cogging torque is significantly affected by structural design.

The load machine drives a currentless test object. This is true regardless of motor type. Cogging torque is measured using a torque sensor connected between the test object and the load machine.

Cogging torque can be determined in two different ways: cogging torque measurement at low speed or cogging torque measurement under closed-loop position control. Both measurements require an active load machine to drive the test object.