1. Types of motor insulation paper

The motor insulation paper commonly used in motors is divided into six grades A, E, B, F, H, and C according to their heat resistance.

Class A insulation includes organic fiber materials such as impregnated cotton yarn, silk, paper, and enamel on ordinary enameled wire. Currently only used in transformers. The allowable operating temperature of Class A insulation is 105°C.

Class E insulation includes films made of polyester resin, epoxy resin, triacetate fiber, etc., enamel on polyvinyl acetal high-strength enameled wire, etc. Used in medium and small AC and DC motors. The allowable operating temperature of Class E insulation is 120°C.

Class B insulation includes mica, asbestos, glass wool, and other inorganic materials made of organic paint or resin (with heat resistance treatment) as a binder and its composition, enamel on polyester high-strength enameled wire, etc. Generally, it is used in large and medium-sized synchronous machines and medium and small AC and DC motors. The allowable operating temperature of Class B insulating materials is 130°C.

Class F insulation includes mica, asbestos, glass wool, and other inorganic substances modified with silicon-organic compounds, or materials made of alkyd and epoxy resins that meet the requirements of this class as materials or combination. The allowable working temperature of Class F insulation is 155°C.

Class H insulation includes materials made of organic silicon and inorganic materials such as mica, asbestos, and glass wool with silicon-organic paint as a binder. It is mainly used in occasions where size reduction and weight reduction are required as much as possible, such as aviation motors, crane motors, traction motors, etc. The allowable operating temperature of Class H composite insulating paper is 180°C.

2. Motor insulation paper thickness and kilowatt ratio

First of all, it needs to be clear that the paint film on the general copper wire has met the insulation conditions, but due to the conditions of production, transportation, embedding, drying, and heating, it is inevitable that the paint film will fall off, therefore, insulating paper is required for further insulation. Secondly, there is no fixed value for the selection of insulating paper thickness. The general principle is that the thicker the better without increasing the difficulty of embedding wires.

General principle: The thickness of the insulating paper should be as thick as possible to ensure the insulation performance of the motor and prevent the motor from heating, burning out, and short-circuiting. The selection of insulating paper requires consideration of the installation environment of the motor. For example, in a humid environment, the moisture-resistant insulating paper should be selected; the heat-resistant temperature of the insulating paper should also meet the requirements of the motor.

3. Installation and cleaning method of motor insulation paper

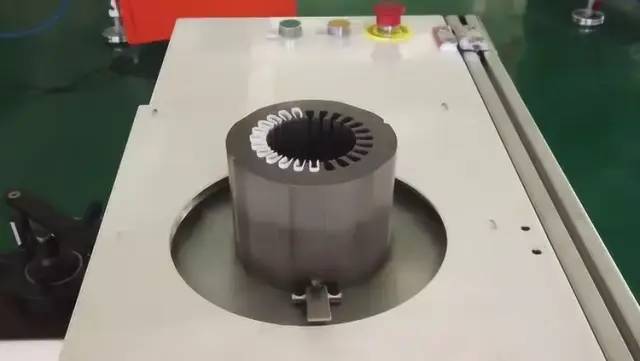

The installation methods of motor insulating paper are generally slot insulation (insulation between the coil and the slot), layer insulation (insulation with two layers of windings under the same slot), end insulation (insulation between phases of the end coils), etc.

Cleaning method of motor insulation paper: Since the insulation paper has a certain hardness, the motor insulation paper that has been impregnated with paint can be taken out by tapping and squeezing. If the paste is too firm, you can properly heat the motor to soften the paint and take it out