When the voltage is reduced, the motor, as the core device of the electric drive, will experience a series of significant changes. The following is a detailed analysis of these changes to help better understand the impact of voltage reduction on motor performance and operating status.

1. Current change

Principle: According to Ohm’s law, the relationship between current I, voltage U, and resistance R is I=U/R. In the motor, the resistance R (mainly stator resistance and rotor resistance) usually does not change much, so the reduction in voltage U will directly lead to an increase in current I. The specific manifestations of current change may be different for different types of motors.

Specific manifestations:

DC motor: When the voltage is reduced, the current of the brushless DC motor (BLDC) and brushed DC motor will increase significantly if the load remains unchanged. The motor needs more current to maintain the original torque output.

AC motor: For asynchronous motors, although the motor will automatically reduce the speed to match the load when the voltage is reduced, the current may rise when the load is heavy or changes rapidly. When the voltage of a synchronous motor is reduced, if the load remains unchanged, the current theoretically does not change much, but if the load increases, the current will also increase.

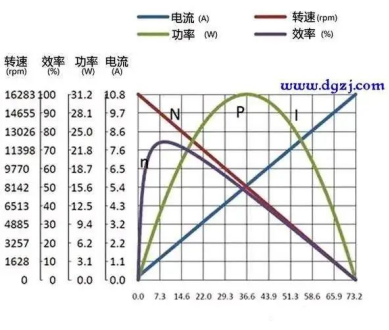

2. Changes in torque and speed

Torque changes: A reduction in voltage usually results in a reduction in motor torque. Because torque is proportional to the product of current and magnetic flux, and when voltage is reduced, although the current increases, the magnetic flux may decrease due to insufficient voltage, resulting in a decrease in overall torque. However, in some cases, such as in DC motors, if the current increases enough, it may compensate for the decrease in magnetic flux to a certain extent, keeping the torque relatively stable.

Speed changes: For AC motors, especially asynchronous motors, and synchronous motors, a reduction in voltage will directly lead to a reduction in speed. This is because the speed of the motor is related to the power supply frequency and the number of motor pole pairs, and the reduction in voltage will affect the electromagnetic field strength of the motor, thereby reducing the speed. For DC motors, the speed is proportional to the voltage, so the speed will also decrease accordingly when the voltage decreases.

3. Efficiency and heat

Reduced efficiency: A reduction in voltage will lead to a decrease in motor efficiency. Because when the motor runs at a lower voltage, it requires more current to maintain the output power, and the increase in current will increase the copper loss and iron loss of the motor, thereby reducing the overall efficiency.

Increased heat: Due to the increase in current and the decrease in efficiency, the motor will generate more heat during operation. This will not only accelerate the aging and wear of the motor but may also trigger the activation of the overheating protection device, causing the motor to shut down.

4. Impact on the life of the motor

Long-term operation in an environment with unstable voltage or too low voltage will seriously shorten the life of the motor. Because the increase in current, torque fluctuation, speed drop, and efficiency reduction caused by the voltage reduction will damage the internal structure and electrical performance of the motor. In addition, the increase in heat will also accelerate the aging process of the motor insulation material.

5. Countermeasures

To reduce the impact of voltage reduction on the motor, the following measures can be taken:

Optimize the power supply system: ensure the voltage stability of the power supply grid to avoid voltage fluctuations causing impact on the motor.

Select a suitable motor: fully consider the voltage fluctuation factor when designing and selecting, and select a motor with a wider voltage adaptability range.

Install a voltage stabilizer: install a voltage stabilizer or voltage stabilizer at the input end of the motor to maintain voltage stability.

Strengthen maintenance: regularly inspect and maintain the motor to promptly discover and deal with potential problems to extend the service life of the motor.

In summary, the impact of voltage reduction on the motor is multifaceted, including current changes, torque and speed changes, efficiency, and heat problems, and the impact on the life of the motor. Therefore, in practical applications, effective measures need to be taken to reduce these effects to ensure the safe and stable operation of the motor.