The intelligent servo permanent magnet direct drive system is a technological revolution in the mechanical transmission industry.

The system integrates technologies such as servo vector control, permanent magnet synchronous motor, and intelligent control.

It replaces the drive system of “asynchronous motor+reducer+hydraulic coupling” and drives the production machinery directly.

The structure of the transmission system is simplified, the efficiency is improved, the noise is reduced, the installation is convenient, and routine maintenance and repair are not required, thereby saving a lot of manpower and material costs, reducing the environmental pollution in the production process, and effectively reducing carbon emissions.

It can be widely used in various power transmission occasions such as belt conveyors, hoists, winches, ball mills, etc.

It is the power transmission system with the best comprehensive performance at present. This technology is a green and low-carbon digital intelligent technology, and its main scope of application includes the transportation of mineral resources in building materials, coal, metallurgy, electric power, and other industries.

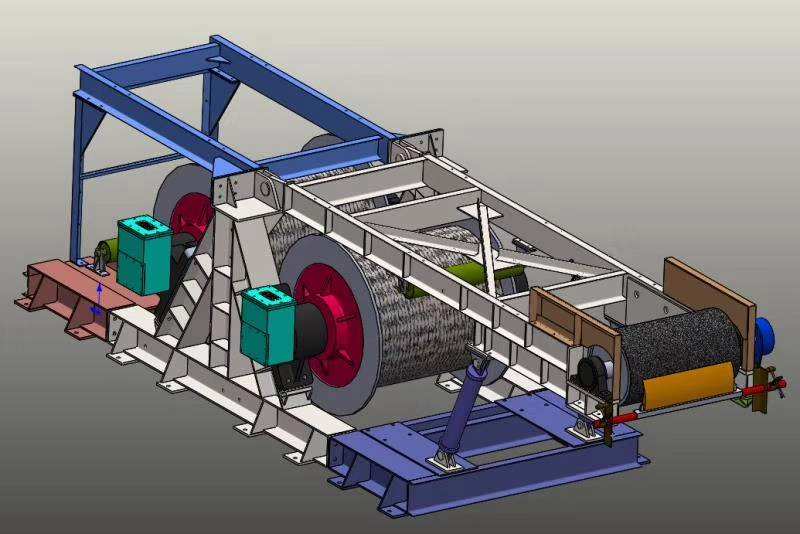

1. Key technology – high-power permanent magnet motor direct drive technology for belt conveyor system.

The long-distance and large-capacity belt conveyor system requires large torque and low speed when starting with heavy loads. When driven by traditional asynchronous motors, there are disadvantages such as difficult starting, large impact, and low efficiency.

Therefore, the system adopts the design method of a low-speed high-torque permanent magnet motor under electromagnetic-temperature-stress multi-field coupling, uses the vacuum potting process of the motor stator winding, and controls the vacuum pressure and pouring temperature and time by configuring the potting material (thermal conductivity > 1.1), so that the motor stator winding temperature rise is less than 55K.

2. Key equipment – high-power permanent magnet direct drive motor intelligent permanent magnet direct drive system mainly includes permanent magnet synchronous motor and intelligent servo controller.

The permanent magnet of the permanent magnet synchronous motor is made of rare earth permanent magnet material NdFeB, which replaces the electric excitation and has no excitation loss; the rotor has no winding, no rotor copper loss, and no rotor iron loss.

Therefore, the efficiency is higher than that of asynchronous motors and electric excitation synchronous motors.

High-performance NdFeB rare earth permanent magnet material has a high magnetic energy product, and its residual magnetic induction intensity and coercive force are large.

A sufficient motor magnetic energy product can be generated with fewer NdFeB permanent magnets. Therefore, the volume and size of the motor can be greatly reduced.

The data shows that the efficiency of a permanent magnet synchronous motor is 3%~12% higher than that of an asynchronous motor with the same capacity, and the output power is also 10%~30% higher when the volume and maximum operating speed are the same as those of asynchronous motors.

The high-performance NdFeB rare earth permanent magnet material has a high magnetic energy product, and its residual magnetic induction and coercive force are relatively large.

It can generate sufficient motor magnetic energy products with fewer NdFeB permanent magnets, so the volume and size of the motor can be greatly reduced.

3. Application prospects

“Large-scale permanent magnet drive belt conveyor high-end equipment” technology is a major technical equipment for mining and material transportation.

It has made remarkable achievements in revitalizing resource reserves, increasing output value and profit, low carbon, energy saving, land saving, water saving, and comprehensive utilization. The results are mainly manifested in:

(1) Revitalizing resource reserves: The general infrastructure around the mine is weak and the transportation is inconvenient, resulting in a large number of mineral resources that cannot be transported out.

This technology can realize long-distance and large-capacity mineral resource transportation under complex terrain, especially for large dip angles of mineral resources, turning and continuous transportation, can provide equipment support for the efficient and continuous transportation of mineral resources, and effectively revitalize mine resources.

(2) Increase in output value and profit: This technology has the characteristics of continuous and efficient transportation.

The hourly transportation volume can reach more than 10,000t/h, the daily operation time can reach more than 20 hours, and the transportation efficiency is significantly improved.

The transportation cost of this technology is 1/10 of the automobile and 1/3 of the railway transportation costs, the transportation cost is greatly reduced, and the output and profit level of the enterprise is greatly improved.

(3) Energy-saving and low-carbon: It is driven by a high-power permanent magnet direct-drive motor, which saves more than 20% more energy than the traditional drive system, and realizes the single-machine long-distance transportation of materials through the turning technology, without the need to use multiple conveyors for overlapping transportation, to avoid transfer energy consumption, the energy saving effect is remarkable.

This technology can replace automobile transportation, avoid automobile exhaust pollution caused by long-distance automobile transportation of materials, and reduce carbon emissions.

Large-scale permanent magnet drive belt conveyor high-end equipment is green, energy-saving, and efficient equipment for long-distance transportation of bulk materials, and is indispensable major equipment for key industries of the national economy such as coal, mining, building materials, metallurgy, and electric power.