Compared with horizontal motors, vertical motors, especially large-sized vertical motors, have their own particularity in their bearing systems, and angular contact ball bearings are used at one end of the motor. Due to the particularity of the structure of angular contact ball bearings, the bearing assembly direction must not be reversed, otherwise the bearing will be directly scrapped. When the bearing is not in place or the axial fit of the bearing itself is misaligned when the motor is running, it may cause abnormal vibration and strange noises in the motor.

01.Noise problem of vertical motors

Vertical motors, especially large-sized vertical motors, have unique bearing systems and are often equipped with angular contact ball bearings at one end. This type of bearing has a precise structure, and if the assembly direction is wrong, it may cause direct damage to the bearing. In addition, if the bearing is not in place or the axial fit is misaligned when the motor is running, it may also cause abnormal vibration and noise in the motor.

► Function of angular contact ball bearings

Single-row angular contact ball bearings are designed to withstand combined loads and can withstand large thrust in a single direction. In vertical motors, this type of bearing is often used at the non-shaft extension end to cope with situations where the axial force exceeds the bearing range of the deep groove ball bearing. Its size is compatible with the single-row deep groove bearing of the corresponding motor, thus avoiding a series of potential problems caused by redesigning the structural parts.

The application of angular contact ball bearings in vertical motors is to solve the problem of bearing large axial forces and balancing the position between the rotor and the stator. In these applications, angular contact ball bearings are usually installed in pairs to meet different working requirements. By properly arranging the bearings, an axial force that is balanced with the weight of the motor rotor can be applied to ensure a stable axial relative position between the rotor and the stator.

► Installation and operation challenges

During the operation of the motor, whether it is a lifting or hanging installation of angular contact ball bearings, there will be a series of challenges. In particular, any axial misalignment or vibration may lead to unstable operation and noise. In addition to the matching relationship of the axial dimensions, after the motor is powered on, the magnetic center lines of the stator and rotor will spontaneously align under the action of electromagnetic force.

In the selection of motor bearing structure, we can take a variety of measures, such as using angular contact ball bearings to pair, effectively control the displacement of the bearing in the axial direction, use a three-bearing structure to enhance stability, and reasonably pre-set the misalignment of the stator and rotor. However, it should be noted that the pre-misalignment size of the stator and rotor must be controlled within an appropriate range to avoid adverse effects. In addition, during the storage, transportation and testing of vertical motors, it should be ensured that the motor is always in the correct vertical state to prevent bearing damage due to improper external forces.

02 Vibration Problems of Large Vertical Motors

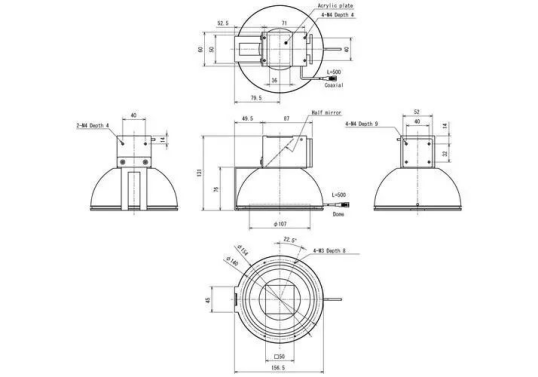

Next, we will focus on the vibration problems of motors in large vertical pumps. The barrel support and total height of such motors are usually large, and the speed is about 1500 rpm. The upper bearings generally use sliding or rolling bearings, but the vibration problems of sliding bearings are usually caused by the adjustment of the guide bushing, so they are not discussed in this article. We will focus on the vibration problems of motors with rolling bearings as the upper bearings. The structure includes the motor, barrel support, pump body, and inlet and outlet pipes.

► Characteristics and influence of vibration

The vibration amplitude at the top of the motor is the largest, and as the position goes down, the vibration gradually decreases, showing obvious directionality. When the motor is tested empty, that is, when the motor is connected to the support barrel but not to the pump rotor, its vibration frequency is mainly based on the rotation frequency. However, when the motor is connected to the pump rotor, the vibration frequency may be mainly 2X.

The motor vibration gradually weakens as the position decreases, showing a directional characteristic. After the motor is connected to the pump, the vibration frequency may change significantly. For example, the motor vibration problem may also be affected by many factors, such as excessive vibration when a new installation is put into production, excessive vibration after the motor is replaced or repaired, and increased vibration during operation but still obvious vibration after disconnecting the pump rotor.

► Analysis of vibration causes

Motor vibration may be caused by a variety of factors, including the motor itself, the support cylinder, the pump body, and the inlet and outlet pipes.

► Causes of the motor itself

Motor vibration may be caused by a variety of internal factors. Among them, insufficient balancing accuracy is a key issue, especially in the cylinder support plus motor system with weak overall stiffness, where a small amount of imbalance may cause significant motor vibration. However, by reducing the amount of imbalance, vibration can often be effectively reduced. In addition, improper bearing installation leading to motor vibration is also a common cause. For example, the upper bearing is stressed and the lower bearing plays a supporting and guiding role, and the rotor is in a suspended state, which explains why the upper bearing is often damaged first. Such problems can be prevented by checking the stress conditions of the two bearings.

► Support system problems

Insufficient stiffness of the support cylinder may cause vibration problems. When the motor is connected to the support cylinder, the problem of insufficient overall stiffness will gradually appear. In order to distinguish whether it is a problem with the motor or the support cylinder, we can test the single motor and the motor plus the support cylinder on the test platform. At the same time, adding support and adjustment methods can improve its impact.

► Installation and resonance effects

Some motors may have structural resonance that significantly affects motor vibration. After actual testing, we found that the resonance frequency can affect the range of up to ±160 rpm, and sometimes even directly affects the rated speed. For such problems, it is necessary to confirm and improve the motor accuracy through experiments to reduce vibration. Structural resonance may significantly affect motor vibration, and it is necessary to confirm and improve the motor accuracy through experiments to reduce vibration.

When dealing with vibration problems, we need to consider various factors and take targeted treatment measures. These measures may include improving balancing accuracy, ensuring overall verticality, adjusting bearing clearance, adding temporary support, and redesigning barrel support. When implementing temporary support measures, we should ensure that the support point is at the upper end of the motor and adjust the support strength appropriately to obtain significant vibration reduction effects.